Modern telecommunications devices are constantly evolving. Many products offer complex innovations. This certainly poses new challenges for manufacturers to ensure that innovations do not violate existing or planned regulations.

The problem is that many manufacturers still ignore pre-compliance testing and only focus on final certification testing. This means that there is a risk that products with innovations may fail official certification. Such failures can lead to re-testing, hardware redesign, delayed time-to-market, and escalating compliance costs.

When it comes to saving time and money, pre-compliance testing can be a strategic approach. This process is not a substitute for certification but serves as a risk-control tool worth considering.

What is Pre-Compliance Testing?

Pre-compliance testing in the context of telecom and wireless products refers to a testing process conducted before final certification testing. It is part of the telecom compliance lifecycle as an initial evaluation conducted by manufacturers on their products during the design and development phase.

The purpose of this process is to identify potential failures in meeting the original regulatory standards before testing in an official certification laboratory. At this stage, it is possible to detect electromagnetic interference (EMI) or radio frequency (RF) performance issues that do not meet standards.

If any non-compliance is detected, the problem can still be corrected early on. This prevents financial losses due to the need to redesign and re-certify finished products, and delays their marketing.

The results of pre-compliance testing do not replace official certification testing conducted in an accredited laboratory. However, this process will greatly assist companies in saving time and costs in the type approval application process.

Areas that are typically tested

- RF performance: Commonly performed during the pre-compliance testing process.

- EMC indicators: Not commonly performed, but can be done in labs that offer pre-compliance testing services.

- Basic electrical safety parameters: Similar to EMC indicators, these are not commonly performed, but can be done.

When should pre-compliance testing be conducted?

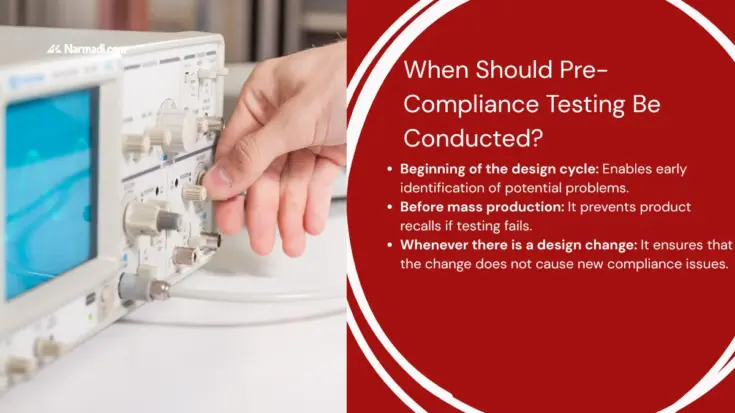

Pre-compliance testing should be conducted well before the product is ready for compliance testing. This process can be carried out during the product development and design stages. The three ideal times to conduct pre-compliance testing are at the beginning of the design cycle, before mass production, and whenever there is a significant design change.

- Beginning of the design cycle: Enables early identification of potential problems.

- Before mass production: It prevents product recalls if testing fails.

- Whenever there is a design change: It ensures that the change does not cause new compliance issues.

What does the Process Do?

During the pre-compliance testing process, radio frequency (RF) testing is commonly performed. This testing is carried out using a spectrum analyzer. To pass the RF test report, several item parameters must be met. These parameters refer to the European Telecommunications Standards Institute (ETSI) EN 300 328 – V2.2.2.

These parameters include frequency range, output power, bandwidth, and unwanted emissions. These four parameters must generally be met and must not exceed the specified maximum limits.

This process will determine whether or not the four parameters are compliant. This is because it is common to find frequencies that are too wide and output power that is too high or too low. These findings must then be communicated to the product technician for readjustment.

For more details on the RF process, you can read our article entitled: Do’s and Don’ts When Submitting RF Test Reports for Type Approval.

How the Process Saves Time and Money

Telecom and wireless devices will be determined whether they meet the test parameters or not during pre-compliance. This makes the certification application process more time and cost-efficient. Not only that, but you can also speed up marketing time and design optimization.

- Avoid redesign: Problems detected during pre-compliance testing will prevent costly and time-consuming major redesigns in the final stages.

- Faster launch: Avoid final test failures, which can delay the launch schedule for a long time.

- Efficient certification: Products that have undergone pre-compliance testing are more likely to pass on the first attempt, speeding up the overall certification process.

- Better resource allocation: The strengths and weaknesses of the device will be specifically identified, enabling targeted improvements and avoiding unnecessary efforts.

- Lower overall costs: Pre-compliance testing is a relatively small investment compared to the high costs incurred when failing official testing and other impacts, such as development delays.

Pre-Compliance Testing vs Certification Testing

| Aspects | Pre-Compliance Testing | Full Compliance Testing |

| Objectives | Early problem identification or internal assessment | Official certification |

| Testing locations | Manufacturers, agents, or labs with pre-compliance testing services | Accredited laboratories |

| Equipment | Simple spectrum analyzer to measure RF testing parameters | More sophisticated equipment for various types of testing, from RF, EMC, Electrical Safety, etc. |

| Regulatory validity | Test results cannot be used as documents for certification applications | Test results can be used as certification application documents |

| Costs | Low to moderate | High |

The pre-compliance testing process is indeed part of the telecom compliance lifecycle. However, it is not part of the approval process itself. Pre-compliance is only intended to identify problems early on, conduct internal assessments, and avoid failure in official lab testing.

The results cannot be used for certification applications. Only the results of full compliance testing can be used as certification application documents. Regulators do not accept pre-compliance reports because the testing is not conducted in an accredited laboratory and does not comply with the standards of the respective authorities.

How Pre-Testing Fits into the Telecom Compliance Lifecycle

The telecom compliance lifecycle is the entire series of processes involved in applying for type approval certification. This process refers to regulatory research, design & planning, pre-compliance testing, official lab testing, type approval, and market entry.

Pre-compliance testing in the end-to-end telecom compliance lifecycle occupies a crucial position in this cycle. It comes right before official lab testing to avoid test failure.

Pre-compliance is closely related to early compliance planning and multi-country certification strategy. This process is part of the key ways early compliance planning reduces costs.

In a multi-country certification strategy, this process is used to prepare various products that comply with the frequency parameters in each country.

Why is pre-compliance so relevant? This process has a significant impact on global product launches and multi-market approvals. Therefore, manufacturers need to discuss their pre-compliance strategy before entering official testing.