Currently, Information and Communication Technology (ICT) products are widely used by the public. In addition to Radio Frequency (RF) Testing, Specific Absorption Rate (SAR) Testing, and Laser Safety (LS) Testing, Electrical Safety (ES) Testing is also important to ensure that the products we use meet established standards.

Electrical Safety Testing is conducted to ensure that electronic devices meet safety and security standards for their users. Each country has its own regulations to ensure that ICT products on the market meet standards, minimize risks, and comply with applicable laws and regulations.

Let’s take a closer look at what Electrical Safety Testing is, so we can understand how important this testing is for ICT products.

What is Electrical Safety Test?

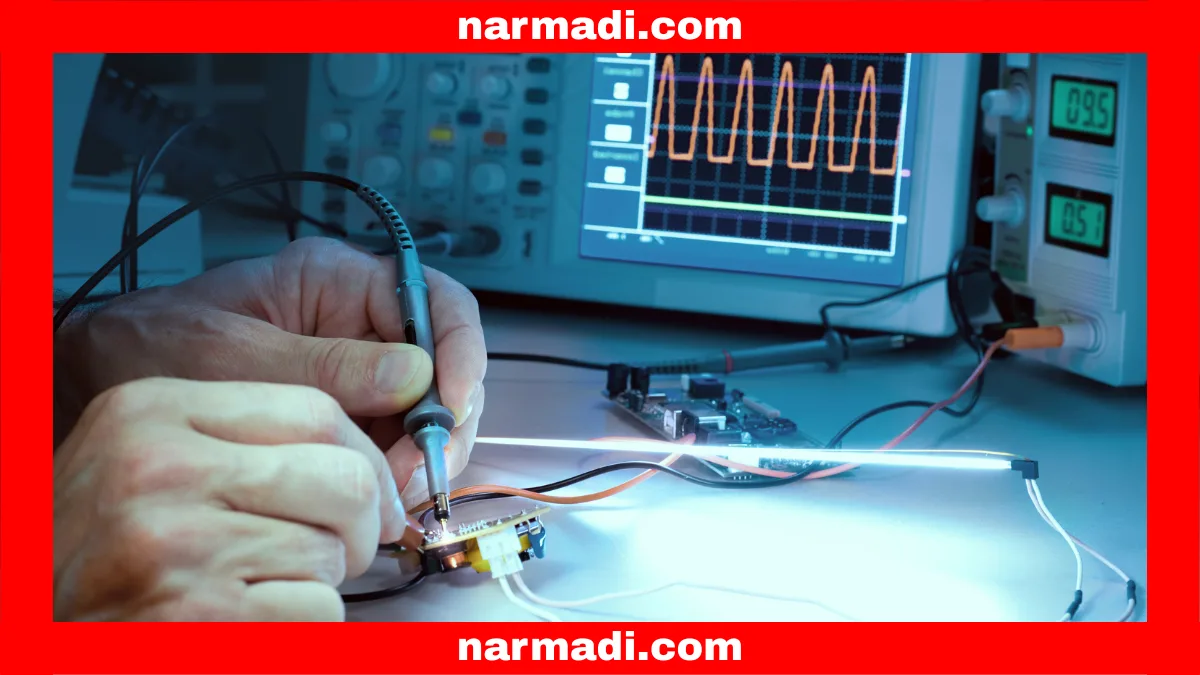

Electrical safety testing is a series of technical and quantitative tests that are an important aspect of ensuring the safety and reliability of electrical products and systems. These tests are designed to identify potential hazards, ensure compliance with regulatory guidelines, and reduce risks associated with electrical devices and installations.

The main purpose of electrical safety testing is to identify and reduce the risk of hazards such as electric shock, burns, and cardiac injury that may arise from faulty electrical equipment. The testing parameters are leakage current, dielectric strength, withstanding voltage, and grounding resistance.

The Types

Leakage current test

A leakage current test is a type of test that measures unwanted electrical currents flowing into the human body. This test ensures that the current is below safe limits, thereby preventing potential harm to users.

It is typically required for medical devices, consumer electronics, and industrial equipment. Acceptable leakage current levels usually do not exceed a few milliamps, depending on the product category. This standard refers to EC 60601-1 or IEC 60950-1.

Dielectric strength test

A dielectric strength test is a test that measures the electrical insulation capability of a device to withstand high voltages. It ensures that the device does not experience damage or failure. This prevents short circuits or short connections.

This test focuses on the insulation between the device’s electrical circuits and the parts that can be touched by the user, such as the casing, cover, or connectors. This standard refers to relevant safety standards, for example, IEC 60950. The main objective is to ensure that users are protected from the danger of electric shock.

Ground connection test

A ground connection test is a type of test that ensures that all metal parts on a device are properly connected to the ground. This test ensures that if the device malfunctions, excess current will flow safely to the ground.

This is important for diverting excess electrical current to the ground, thereby preventing harm to users. Ground connection tests are often conducted in accordance with IEC 60335 and UL 61010 standards.

Scope

Electrical Safety Testing, in this case, aims to comply with IEC (International Electrotechnical Commission) standards. The following are some of the parameters tested in ElSTest:

- Protection against electric shock

- Protection against mechanical hazards and fire

- Measurement of electrical power and current

- Measurement of temperature rise

- Normal and abnormal use testing

- Other test parameters

Why Is It Important?

Electrical safety testing is important because it allows consumers to feel safe and confident when using electronic equipment. Here are some reasons why:

- As verification of compliance with applicable specific instructions

- Provides information on whether there are electrical problems with electronic equipment

- Prevents product recalls if there are failures in electrical safety aspects

- Maintains consumer safety related to electrical hazards

- Builds consumer trust

Want to Pass the Electrical Safety Test?

For manufacturers or importers of electronic devices, ensuring the device passes the Electrical Passing the Electrical Safety Test is a mandatory step for manufacturers or importers of electronic devices before marketing their products. Therefore, you need to know how to pass this test.

One of the best solutions to comply with these regulations is to use our Product Compliance Services. This service will help you get through the testing process quickly, in accordance with the regulations in each country, and ensure that your devices meet safety standards. This prevents the risk of your devices being withdrawn from the market for non-compliance. [UN]