Currently, Information and Communication Technology (ICT) products are widely used by the public. In addition to Radio Frequency (RF) Testing and Specific Absorption Rate (SAR) Testing, Laser Safety (LS) Testing is also important to ensure that the products we use meet established standards.

Laser Safety Testing is conducted to ensure that electronic devices meet safety and security standards for their users. Each country has its own regulations to ensure that ICT products on the market meet standards, avoid risks, and comply with applicable regulations.

Let’s take a closer look at what Laser Safety Testing is, so we can understand how important this testing is for ICT products.

What is a Laser Safety Test?

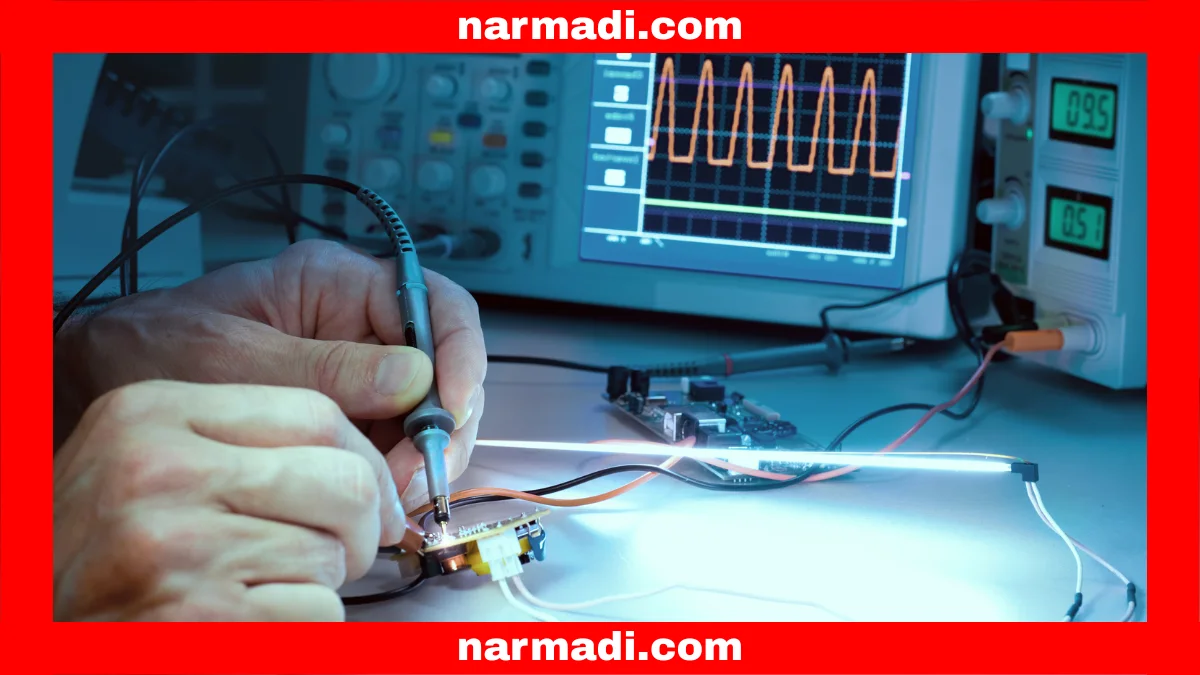

Laser safety testing is the process of evaluating electronic devices that use lasers to ensure that the optical radiation they produce is safe for users. Without testing, devices that emit laser radiation can be potentially harmful to the eyes or skin.

Devices that are typically tested include Li-Fi (Light Fidelity) devices that use light for data communication and LiDAR (Light Detection and Ranging) devices that emit lasers for scanning or distance measurement. Laser products sold must comply with IEC 60825 as a standard testing requirement.

How Laser Safety Test Process?

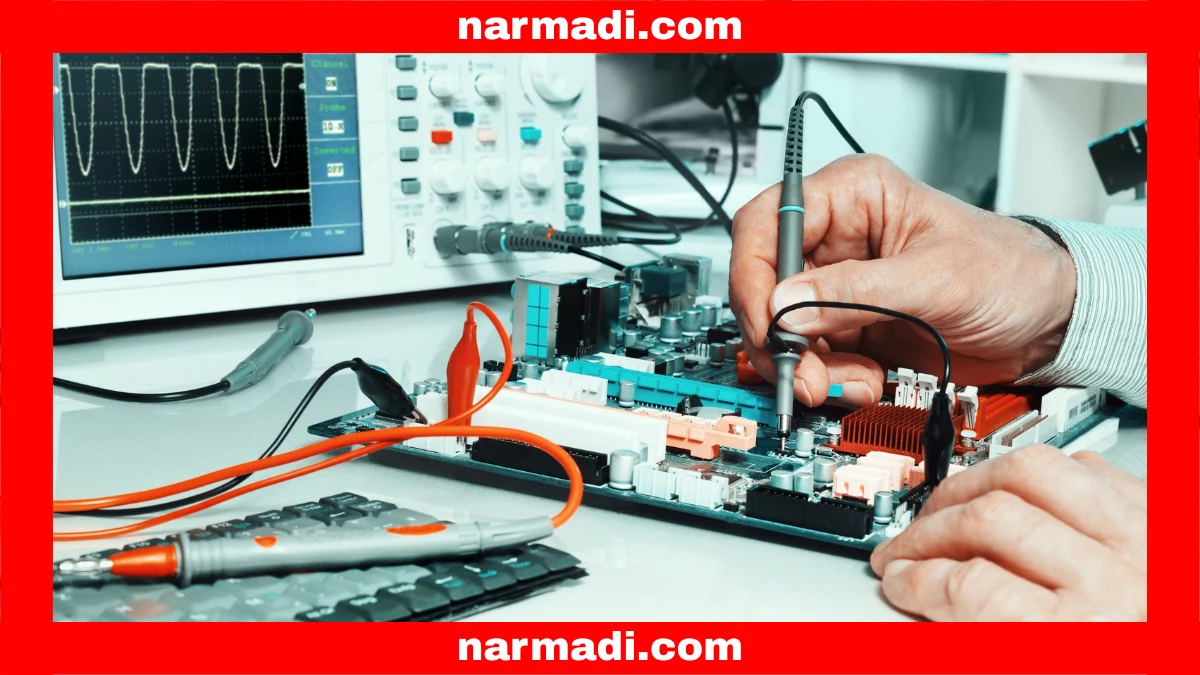

The Electrical Safety Laboratory ensures the electrical safety of a device for human use. Based on IEC 60825-1, the parameters to be tested for the device are:

- Determining laser characteristics: Lasers will be identified based on wavelength, power or energy output, operating conditions, and apparent source size.

- Measuring emission conditions: Testing under normal operating conditions, single fault conditions, and worst-case conditions.

- Calculation and classification: With the collected data, the product is then classified into the appropriate laser safety class.

Classification of Laser Classes

This classification is based on a comparison of the measured laser emission level with the Accessible Emission Limit (AEL) specified by IEC 60825-1:

- Class 1: Safe under all normal operating conditions. The output power is very low, or the laser radiation is safely enclosed.

- Class 1M: Safe as long as not viewed with optical aids (e.g., telescopes or binoculars).

- Class 2: Visible light radiation (400 nm to 700 nm) is considered safe due to the human eyelid response.

- Class 2M: Same as Class 2, but hazardous when viewed through optical aids.

- Class 3R: Potentially hazardous when viewed directly, but the risk is low.

- Class 3B and 4: The highest hazard classes are not suitable for general consumer products.

Why Is Laser Safety Testing Important?

Laser Safety Testing is important because it allows consumers to feel safe and confident when using electronic equipment. Here are some reasons why:

- Preventing accidents: Laser Safety Testing helps prevent accidents and ensures a safe working environment.

- Compliance with standards: Laser Safety Testing ensures that laser-based products comply with standard requirements.

- Protecting customers: Laser safety testing helps protect customers from eye and skin injuries.

- Avoiding product failure: Laser safety testing helps avoid product failure that can occur if the protective measures are not properly designed.

Want to Pass the Laser Safety Test?

Passing the Laser Safety Test is a mandatory step for manufacturers or importers of electronic devices before marketing their products. Therefore, you need to know how to pass this test.

One of the best solutions to comply with these regulations is to use a Product Compliance Services. This service will help you get through the testing process quickly, in accordance with the regulations in each country, and ensure that your devices meet safety standards. This prevents the risk of your devices being withdrawn from the market for non-compliance. [UN]