RFID is a wireless technology that uses radio waves and has the ability to automatically identify, track, and store data on objects. How does an RFID systems work?

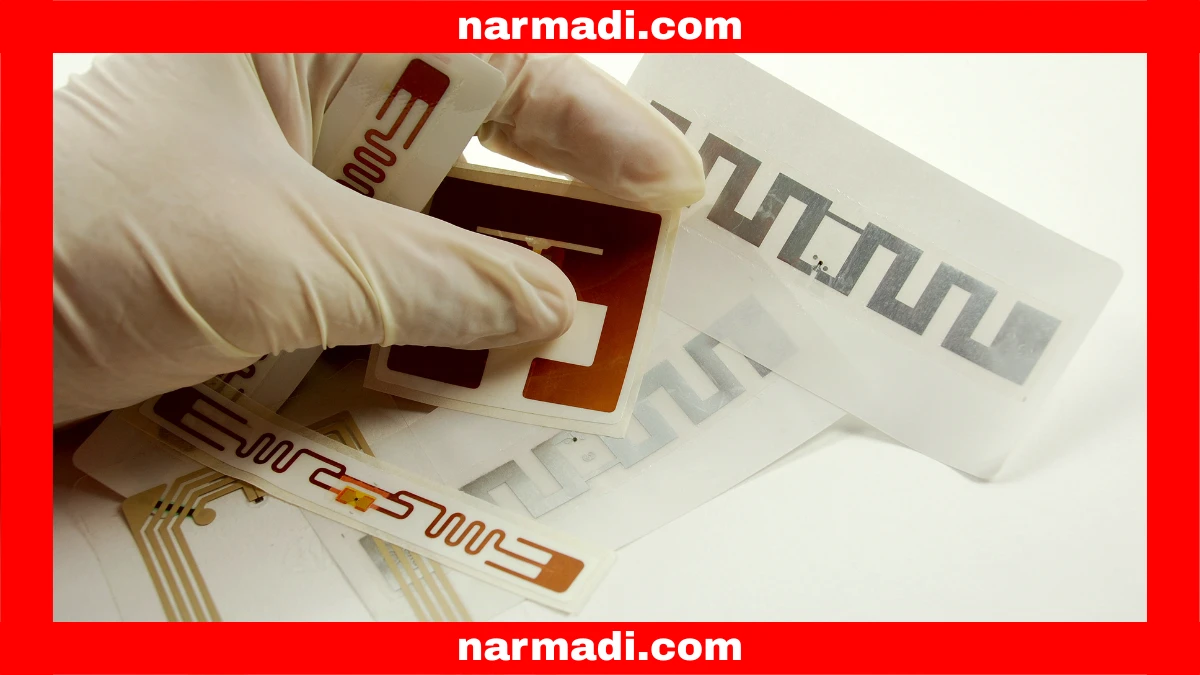

An RFID systems consists of three components: RFID inlays, RFID labels, and RFID tags. These components have slight physical and functional differences between them.

This article discusses each of the components that form the core of an RFID systems and their differences. Let’s discuss them together.

Parts of an RFID Tag

To help you understand the RFID systems and the differences between tags, inlays, and labels, you need to know the parts of an RFID tag. The following are the parts that make up an RFID tag:

- Integrated circuit: This part is also known as an RFID chip. It is the part of the tag that is responsible for storing, managing, and processing data.

- Antenna: This part receives radio waves from the interrogator and sends data back to the reader. This part takes up the most space.

- Substrate: The substrate is the material that holds the IC and antenna of the tag together.

- Surface: The surface is a thin layer made of clear/white plastic or paper. It is used to cover the antenna and chip.

- Casing: This refers to the cover that surrounds the IC, antenna, and substrate. It is made of PET, plastic, or paper.

Understanding Each RFID Systems

1. RFID Inlay

The first RFID systems is the inlay, which is a basic component consisting of an integrated circuit, antenna, and substrate. The antenna is made of aluminum, silver, and copper, and is attached to polyethylene terephthalate (PET). This component functions to identify and track objects wirelessly using radio waves.

There are two types of RFID inlays: wet and dry. Wet RFID inlays have a surface that contains adhesive between the antenna and the cover paper. This type is relatively easy to apply directly to surfaces such as packaging or products and can be removed and reattached.

Meanwhile, dry inlays do not have adhesive, so the antenna and chip placed on the PET substrate are not yet in the form of a label. This type requires the use of external adhesive or other materials to help attach it to assets.

Inlays are relatively affordable and easy to use. This RFID systems is also very flexible because it can be integrated into various products, such as cards, key chains, or ready-made hard labels. In addition, its application can be implemented in various industries, such as logistics, retail, and access control.

2. RFID Label

An RFID label is a system component that has the same contents as an RFID inlay, namely an antenna, chip, and substrate. This component functions to automatically identify and track objects without the need for direct contact.

An RFID label is an RFID inlay embedded in paper. This system is also known as a smart label. It is applied in several sectors, such as logistics, healthcare, and sporting events.

This system is used to track shipments and manage the movement of goods in the supply chain in the logistics sector. In the healthcare sector, it is used to track medical equipment and manage drug inventories. Meanwhile, in sporting events, it is used to track the time and route of runners in a race.

3. RFID tags

RFID tags are components of the system that have encapsulated chips and antennas. Their purpose is to protect the tag components and ensure ease of implementation.

RFID tags can be active or passive. Active tags are equipped with batteries, which ensure a relatively wider reading range. Passive tags, on the other hand, rely on signals from the reader to be activated. This system is used for automatic tracking of various objects in the retail, logistics, healthcare, and other industries.

The Difference Between RFID Inlays, Labels, and Tags

Although inlays, labels, and tags share the same basic purpose in building RFID systems, they differ in construction, readiness for use, surface, and purpose.

Construction

- RFID Inlay: Has an unwrapped chip and antenna construction.

- RFID Label: Has the same construction as an inlay embedded under an outer layer (paper/polyester) with adhesive.

- RFID Tags: The construction is in the form of a standalone device, which can be in the form of a label, card, or other hard form.

Usability

- RFID Inlay: Not ready for use as it needs to be converted into a finished product.

- RFID Label: Ready for use and can be applied immediately as it has adhesive.

- RFID Tags: Ready for use as they are already in device form.

Surface

- RFID Inlay: Has a clear and transparent surface, with no special printed surface.

- RFID Label: Has a printed surface for text, barcodes, etc.

- RFID Tags: Have a printed surface or not, depending on the form.

Purpose

- RFID Inlay: Intended to be the basis for making labels or other RFID products.

- RFID Label: Designed for easy-to-apply product labeling and tracking.

- RFID Tags: Designed for general asset tracking, either in the form of labels or hardware devices.

That is part of RFID tags, the definition of each RFID systems, and the differences between these systems. Understanding this will broaden your knowledge about these wireless devices, not only in terms of their definition, but also beyond that. [UN]